A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were sliding against each other.

It have spherical rolling elements and are used for lower load applications, use cylindrical rolling elements for heavier load carrying requirements.

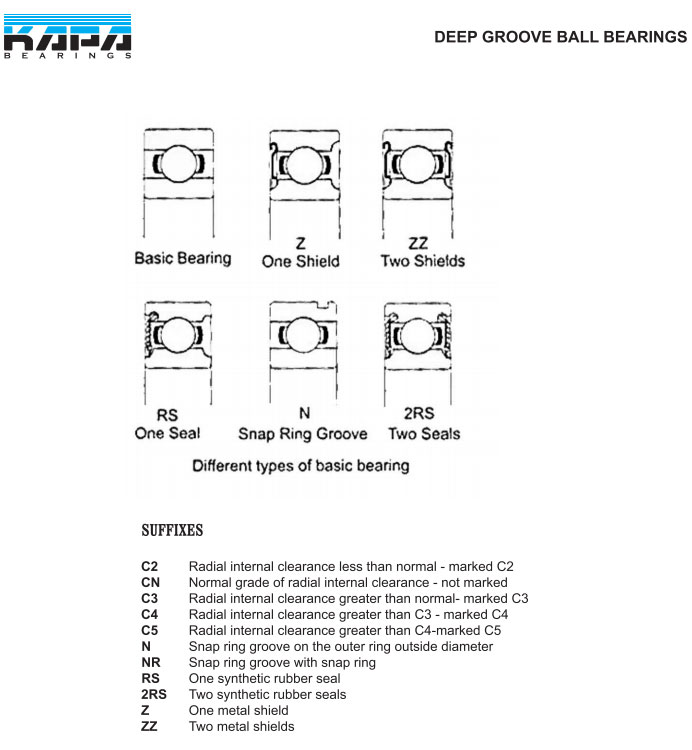

Ball bearings tend to have lower load capacity for their size than other kinds of rolling-element bearings due to the smaller contact area between the balls and races. However, they can tolerate some misalignment of the inner and outer races. Ball Bearings are mechanical assemblies that consist of rolling spherical elements that are captured between circular inner and outer races. They provide a means of supporting rotating shafts and minimizing friction between shafts and stationary machine members. Ball bearings are used primarily in machinery that has shafts requiring support for low friction rotation. There are several configurations, most notably shielded or sealed. Ball bearings are standardized to permit interchangeability. Ball bearings are also known as rolling element bearings or anti-friction bearings.

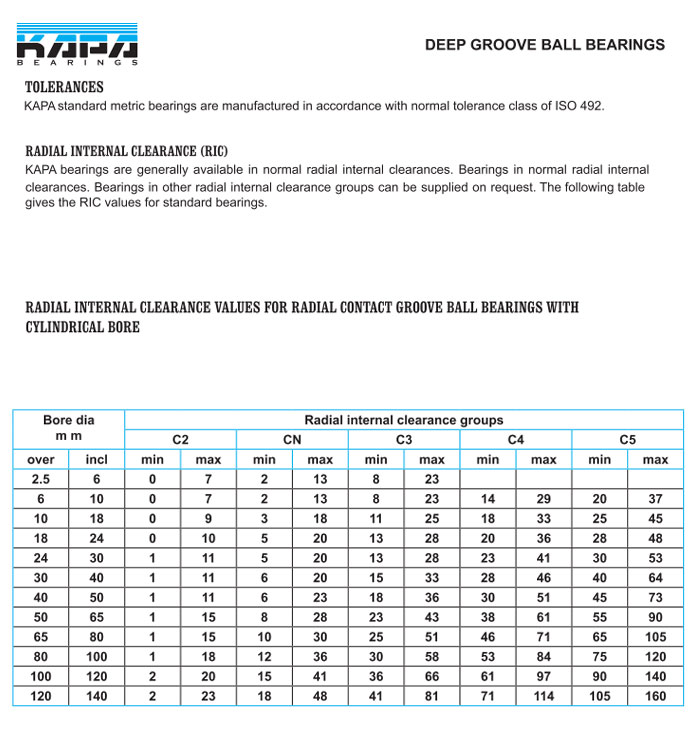

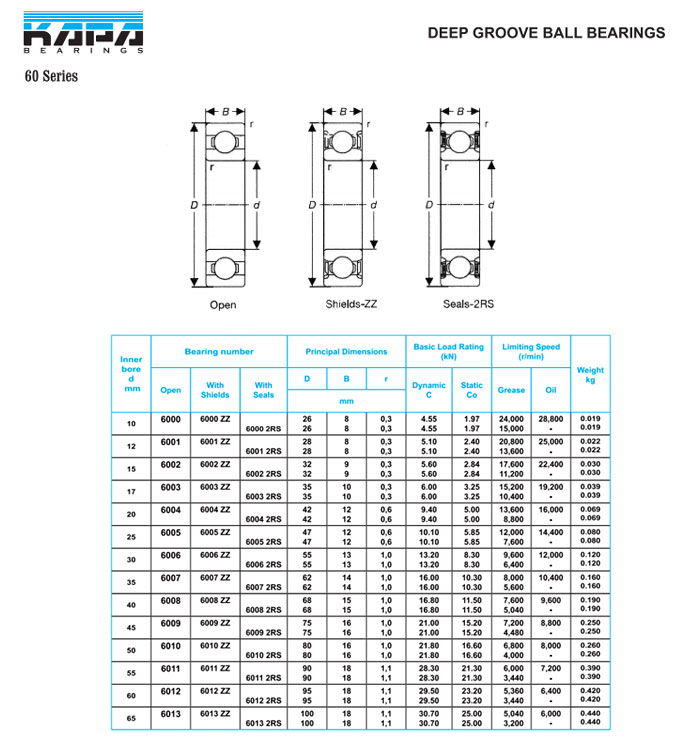

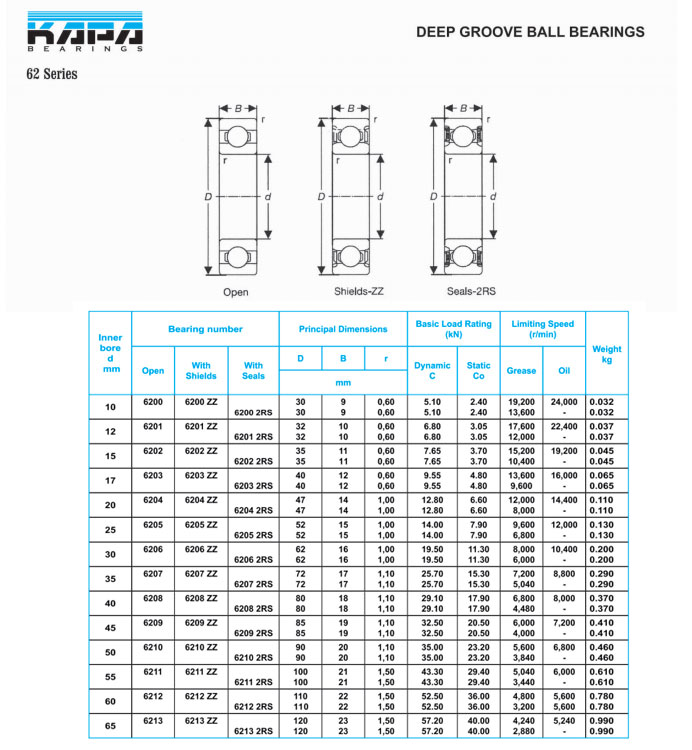

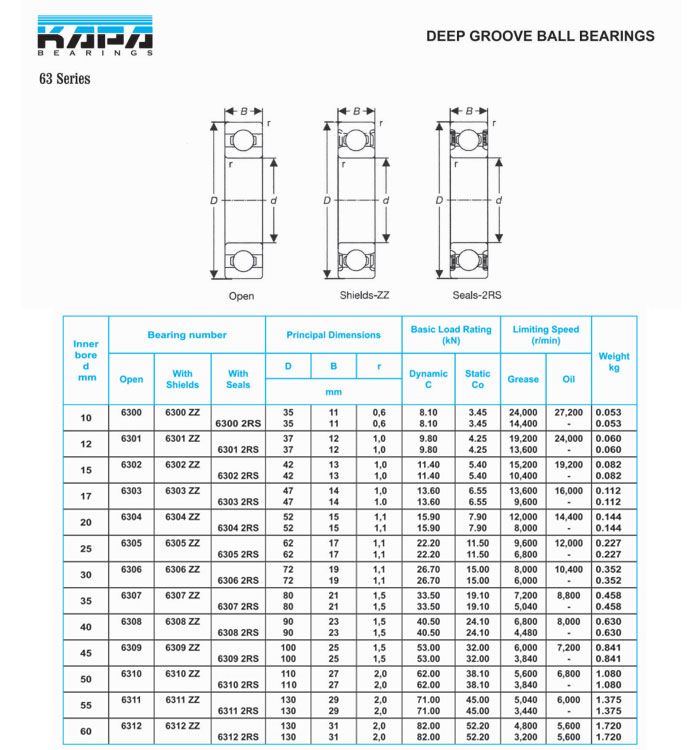

Deep groove ball bearings are available in a variety of sizes, and are the most popular of all rolling bearings. This type of bearing supports radial load and a certain degree of axial load in both directions simultaneously. Low noise bearings (EMQ GRADE). All ball bearings are ABEC-3 grade with Z3V3 noise / vibration levels the main application areas: washing machines, fumes, air conditioning motors, massage devices cash registers, viper fields. High temperature & High-speed bearings & also uses special customized synthetic grease to achieve high temperature & high-speed performance the main application areas: Electric Tools, vacuum cleaners, engines of cars or motors, textile machinery and other areas.